Our reference projects

LEAN⏐SUSTAINABLE│BUSINESS

I have been leading interdisciplinary teams and complex projects for over ten years, from the development of disruptive business models to successful market launches.

Through projects, we grow beyond ourselves and shape the world of tomorrow.

Vincent Barnstorff

Fit for Scaling

© Regionalwaren BFM KG

▶︎ 02.2025

♦︎ ongoing →

⦿ Lean Production; Business Model Extension

@ Regionalwaren BFM KG

> Lean Consultant; Production Expert

{} >5 Team members

€ > 80 T

Innovation

★★★☆☆

Complexity

★★☆☆☆

Risk

★★☆☆☆

Sweet tradition meets modern tastes

Project description

Introduction of lean production in the ice cream factory to increase sales volumes by standardizing and leveling production capacities.

Product/Technologies

Ice cream, Bio

Role and responsibility

Lean Consultant and Production Expert: Structuring of customer requirements, analysis of historical customer call-offs, product pareto, leveled production plan, warehouse design, production process

Methodology

Customer Experience, Lean Manufacturing, Data Analysis

Lessons Learned

Keep: Market and customer-oriented communication

Start: Work according to forecast and stock level

Stop: Call-off production and small production batches

Question: Are the call-off forecasts accurate?

Project results

Phase 1: Introduction of a leveled production plan with control according to stock vacancies in the target state

References

Decarbonize Industries

© Robert Bosch GmbH 2023

▶︎ 02.2022

♦︎ 12.2024

⦿ Business Innovation; Decarbonization; Industry

@ Robert Bosch GmbH; EWE AG

> Project Manager; Co-Founder

{} >10 Team members

€ >4 Mio

Innovation

★★★★★

Complexity

★★★★☆

Risk

★★★★☆

Out of the Carbon Maze

Project description

Market launch of a software platform with SaaS business model for the lean, data-driven decarbonization transformation of industrial companies.

Product/Technologies

Corporate Startup, Green tech, Climate tech, Energy market, Software Development, Software as a Service

Role and responsibility

Project manager; management of: Resources, communication, schedules, scope, risks, integration, stakeholders, costs/budget

Co-Founder; responsible for: Operations, Product Management, Sales, Customer Projects

Methodology

Agile project management, Lean StartUp, Customer Experience, User Experience

Lessons Learned

Keep: Market and customer-oriented product and service development, interdisciplinary communication

Start: broader stakeholder management

Stop: Focus on a business model

Question: Is a commission business model for this form of software service more effective than a SaaS?

Project results

Validated reduction of the planning and decision time “Time to Action” for local decarbonization measures from 3 (best case) to 48 (worst case) months to <4 weeks in the context of proof of concepts with a mature minimum viable product.

References

Zero Emission – the CO2-neutral plant

© Robert Bosch GmbH 2021

▶︎ 06.2018

♦︎ 06.2023

⦿ Infrastructure; Dekarbonisization; Industry

@ Robert Bosch GmbH

> Project Manager

{} >20 Team members

€ >25 Mio

Innovation

★★★★☆

Complexity

★★★★☆

Risk

★★★☆☆

We want to create a CO2-neutral Bosch location that promotes sustainable value streams through the intelligent and efficient use of renewable energies and the avoidance of external compensation measures.

Project description

Expansion of the on-site PV system to up to 10 MWp, use of regional wind power via PPA, conversion of the heating and cooling supply system to an efficient heat pump system to eliminate the use of natural gas

Product/Technologies

Green tech, Climate tech, photovoltaics, wind power, PPA, energy market, heat pump, battery storage, hydrogen, IoT, energy flexibility, flexible production, software development, software as a service

Role and responsibility

Project manager; management of: Resources, communication, schedules, scope, risks, integration, stakeholders, costs/budget

Methodology

Hybrid and agile project management, lean management

Lessons Learned

Keep: Dismantling corporate silos, value-based solution finding

Start: fail fast – fail early, business model approach for project results

Stop: in the context of climate actions, do not use the economic efficiency of measures as the sole measure

Question: How can we digitize the developed methodology to establish lean, data-driven decision-making?

Project results

Reduction of local CO2 emissions by 63% according to the project baseline / by 99% with corporate measures used. Implementation and demonstration of hybrid project management in an organization with a classic waterfall organization.

References

Fit for Future

© Robert Bosch AG 2025

▶︎ 09.2019

♦︎ 08.2020

⦿ Production, Purchasing

@ Robert Bosch AG

> Consultant; Director of Study

{} 5 Team members

€ 0,7 Mio

Innovation

★☆☆☆☆

Complexity

★★★☆☆

Risk

★★★☆☆

Management of a study and preparation of a multi-project with the aim of reducing site fixed costs across the board.

Project description

Consideration of insourcing and outsourcing scenarios, taking into account standard, core and key competencies, resources, costs and savings. Setting up multi-project management with bottleneck control via resources.

Product/Technologies

Machining, hardening, assembly

Role and responsibility

Study director; management of: Communication, schedules, integration, stakeholders, costs/budget

Consultant; consulting in the area of multi-project management (methods and tools)

Methodology

Lean project management, bottleneck management, competence management, lean production

Lessons Learned

Keep: Holistic consideration of possible scenarios and evaluation according to overall objective. Very good transition from on-site to off-site work (Covid19 lockdown)

Start: Use of software for planning and management of multi-projects

Stop: Silos in production and purchasing organizations

Question: Can the site manage its costs economically in the long term?

Project results

Handover of study results as project charter for multi-project. Introduction of multi-project management after bottlenecks.

References

Fit for Automation

© Endress + Hauser SE + Co. KG 2022

▶︎ 03.2019

♦︎ 05.2019

⦿ Product development, Production

@ Endress + Hauser SE + Co. KG

> Consultant DFMA & Lean Production

{} 3 Team members

€ 0,5 Mio

Innovation

★★☆☆☆

Complexity

★★★☆☆

Risk

★★☆☆☆

Lean production & automation consulting for sensor production.

Project description

Advising a production site in the context of capacity expansion planning and related considerations regarding optimization of existing production, scaling and automation.

Product/Technologies

Bare die on substrates, assembly, bonding, electrode welding, manual assembly, automation, Industry 4.0

Role and responsibility

Consultant DFMA; advising product development on the manual / automated assembly capability of planned product generations

Consultant Lean Production & Automation; consulting production site regarding optimization possibilities of existing plants and preparation of a scaled investment plan for capacity expansions

Methodology

Lean Production, Design for Manufacturing & Assembly (DFMA), Scaling of production

Lessons Learned

Keep: Use external and in-house know-how to achieve optimum results

Start: No politics – the focus is on customer benefit

Stop: Let conflicts of objectives arise

Question: How can the customer introduce lean and automated production?

Project results

Handing over results to customers

References

Fit for Production

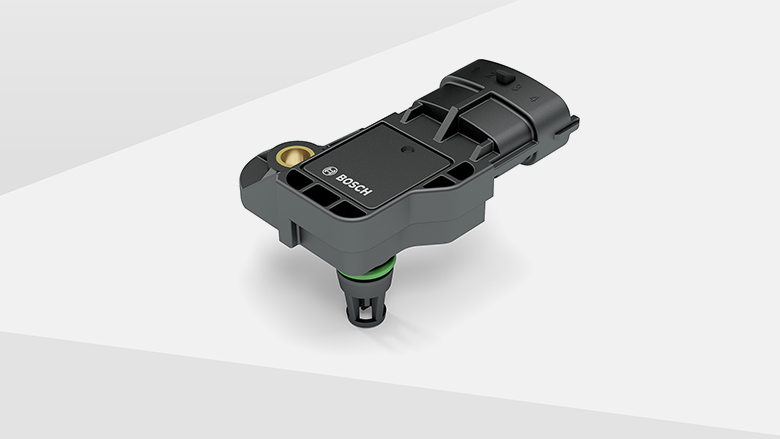

© Robert Bosch GmbH 2025

▶︎ 09.2013

♦︎ 08.2018

⦿ Product development, Production

@ Robert Bosch GmbH

> Project manager industrialization & SE

{} >10 Teammitglieder

€ >21 Mio

Innovation

★★★☆☆

Complexity

★★★★☆

Risk

★★★☆☆

Project Manager Industrialization for the lean, cost-optimized production of automotive pressure sensors.

Project description

Development of a pressure sensor platform with the functional scope of the predecessor platforms at the lowest product costs – “low cost sensor”

Product/Technologies

SMD/SMT, bare die on SMD assembly, assembly, gluing, bonding, electrode welding, pin insertion, automation, Industry 4.0

Role and responsibility

Project Manager Industrialization; Management of: Resources, communication, schedules, scope, risks, integration, stakeholders, costs/budget

Simultaneous engineering; ensuring lean, highly automated manufacturability (lean production)

Methodology

Lean Production, Simultaneous Engineering (SE), Design for Manufacturing and Assembly (DMFA), Design Review based on Failure Mode (DRBFM), Failure Mode and Effects Analysis (FMEA)

Lessons Learned

Keep: Out of the Box – mindset, goal-oriented discussions in the SE core team from product development, purchasing and production

Start: Incorporate market analysis more strongly into milestone reviews, involve stakeholders at all organizational levels

Stop: Let silos at organizational level block the project

Question: Can the time to market be shortened?

Project results

Handover of the industrialization project to the line organization and follow-up project manager. Start of Production 2020 with a scaled and highly automated production chain with minimal operator effort and high production availability and quality.